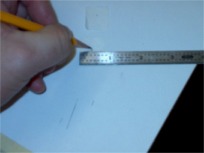

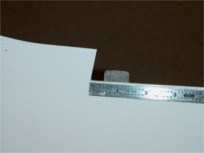

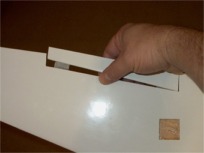

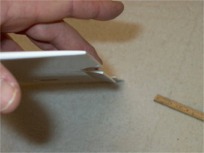

19 - Marking center lines for the aileron hinges .

37 - Motor assembly completed.

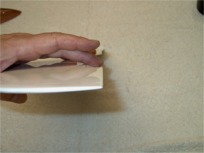

38 - Preparing to assemble the MiniFan480, the shaft adapter is slotted at the tip so a screwdriver can be used later to help tighten the nut.

(NEXT PAGE)