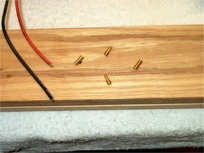

59 - Socket rear is pre-tinned and filled with solder.

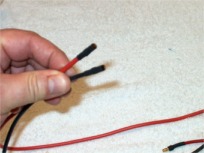

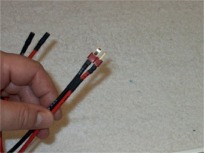

62 - Heat shrink tubing is added for insulation.

77 - Note the ends were also rounded, which "relieves" them and helps prevent cracking.

78 - A Dremel with a sanding drum was used to even up the ducting.

(NEXT PAGE)